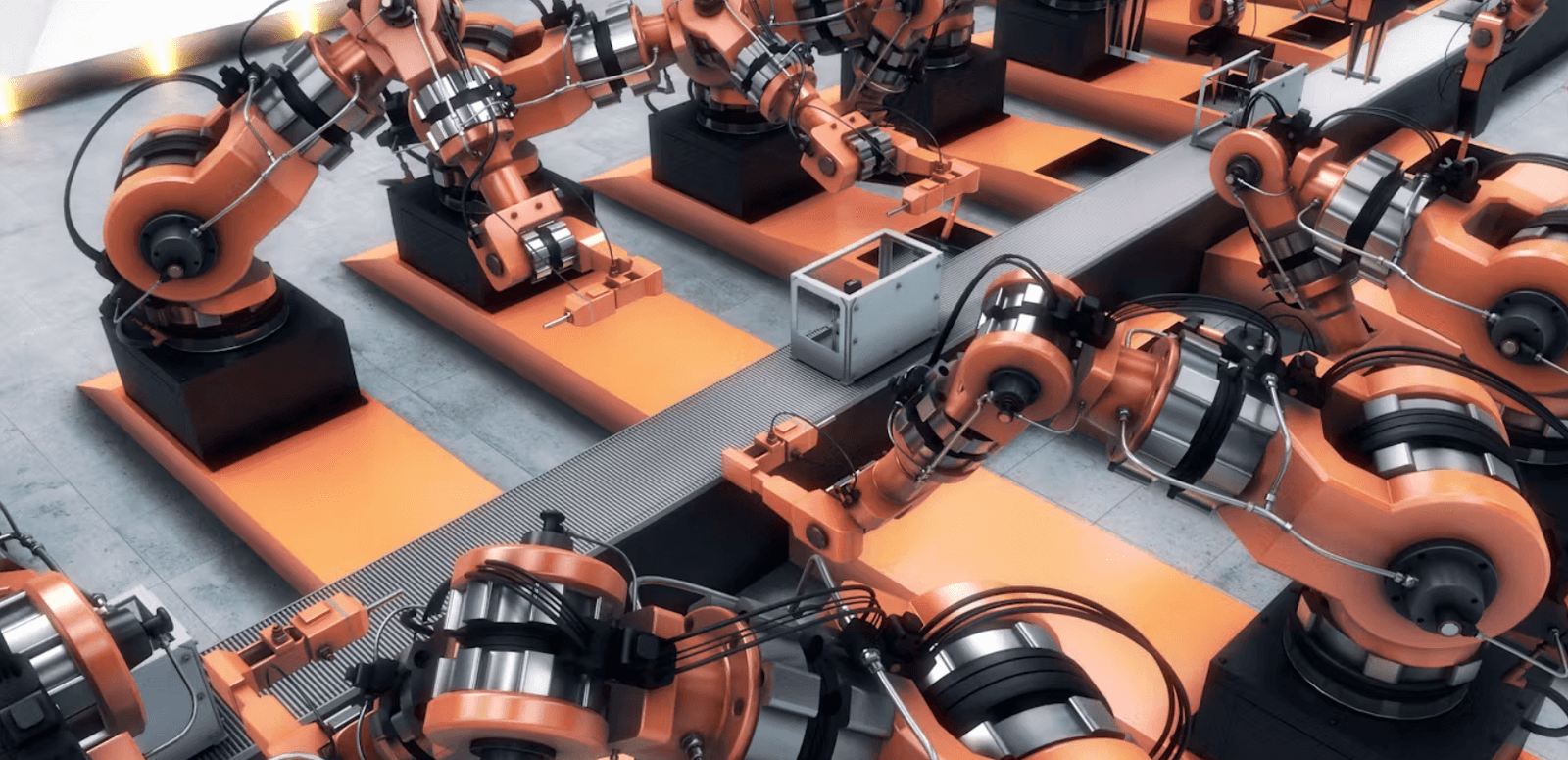

Robotics in Manufacturing: The Next Industrial Revolution

Robotics in manufacturing is transforming traditional production methods. This shift promises increased efficiency and precision, addressing labor shortages while allowing human workers to engage in more intricate tasks. Collaborative robots are particularly noteworthy, as they enhance human-robot synergy. However, this evolution brings challenges that must be navigated carefully. As industries grapple with these changes, the implications for the future of manufacturing remain to be fully understood. What will this mean for the workforce and innovation?

The Role of Robotics in Modern Manufacturing

Robotics has transformed modern manufacturing by enhancing efficiency and precision in production processes.

By automating repetitive tasks, robots liberate human workers from mundane duties, allowing them to focus on creative and strategic roles. This shift not only fosters innovation but also empowers individuals to explore new ideas and solutions.

Ultimately, robotics promotes a more dynamic and liberated workforce, driving progress in the manufacturing sector.

Benefits of Implementing Robotics

As manufacturers increasingly adopt automation technologies, the benefits of implementing robotics become evident across various aspects of production.

Enhanced efficiency and precision lead to higher output and reduced waste, fostering a more agile production environment.

Additionally, robotics can alleviate labor shortages, allowing human workers to focus on complex tasks.

This shift promotes innovation and creativity, empowering companies to thrive in a competitive landscape.

Challenges and Considerations for Adoption

While the advantages of robotics in manufacturing are compelling, several challenges and considerations must be addressed before widespread adoption can occur.

High initial costs, integration with existing systems, and potential job displacement are significant hurdles.

Additionally, ensuring workforce training and addressing regulatory concerns are crucial.

Companies must weigh the long-term benefits against these obstacles to achieve a balanced and liberated approach to innovation.

The Future of Robotics in the Manufacturing Sector

Although the current landscape of manufacturing is marked by rapid technological advancements, the future of robotics in this sector promises even more transformative changes.

Enhanced automation, artificial intelligence, and collaborative robots will empower workers, increasing productivity and creativity.

As manufacturers embrace these innovations, the potential for customization and flexibility will foster a new era of freedom, redefining the boundaries of production capabilities.

Also read: Navigating the Ethics of AI: Challenges and Opportunities

Conclusion

In conclusion, robotics in manufacturing heralds a transformative era, aligning with the adage, “Necessity is the mother of invention.” As industries adapt to the increasing demand for efficiency and precision, the integration of robotics will not only address labor shortages but also enhance innovation and creativity among human workers. While challenges remain, the future of manufacturing is poised to leverage these advancements, ultimately reshaping production processes and establishing a new standard of excellence in the sector.